By Caitlyn Clark, Brinn McDowell, Jeremy Stefek at the National Renewable Energy Laboratory for the U.S. Department of Energy Wind Energy Technologies Office

DOE/GO-102023-6075

Overview

Purpose

Safety is a top priority for the offshore wind energy industry; however, there has been uncertainty surrounding what unique safety standards and training will be needed and how various offshore wind safety stakeholders will be involved. This fact sheet aims to help reduce these uncertainties by:

-

1. Delineating jurisdictional lines while clarifying roles and responsibilities among stakeholders.

-

2. Identifying key actions or partnerships that can encourage further success with safety training and workforce development.

The scope of safety training for this resource includes workers who build and operate offshore wind energy projects at sea. There are four types of safety training covered in this resource:

-

1. Vessel-specific safety training requirements.

-

2. Requirements for workers constructing wind turbines.

-

3. Requirements for workers operating and repairing offshore wind turbines.

-

4. Health, safety, and environment training for onshore professional roles who oversee offshore activities.

Some examples of job roles that fall within this scope include seamen and other vessel operators, heavy-left crane operators, lead package engineers, and offshore wind energy technicians. Other onshore roles (such as those in construction and manufacturing) require relevant safety training, but those standards are not covered in this resource.

Background

The standardization of safety training requirements for people working at sea to build and operate offshore wind energy projects, adoption of those standards, and alignment with offshore safety training curriculum development was identified as a high-priority workforce gap in the U.S. Offshore Wind Workforce Assessment.[1] The assessment noted that the lack of approved worker credentials and limited consensus on who should regulate offshore safety requirements could cause curriculum developers and providers to misalign training requirements. This mismatch could lead to an inadequately trained and unavailable offshore wind energy workforce. The uncertainty around safety training and requirements has increased in importance as we approach the commissioning of the United States’ first wind farms. Several organizations have started to develop and certify programs to provide safety training for workers. Because of the high-priority nature of safety training, the Offshore Wind Workforce Network[2] recommended conducting interviews to provide a more comprehensive assessment and develop a solutions-oriented approach to address the workforce gaps.

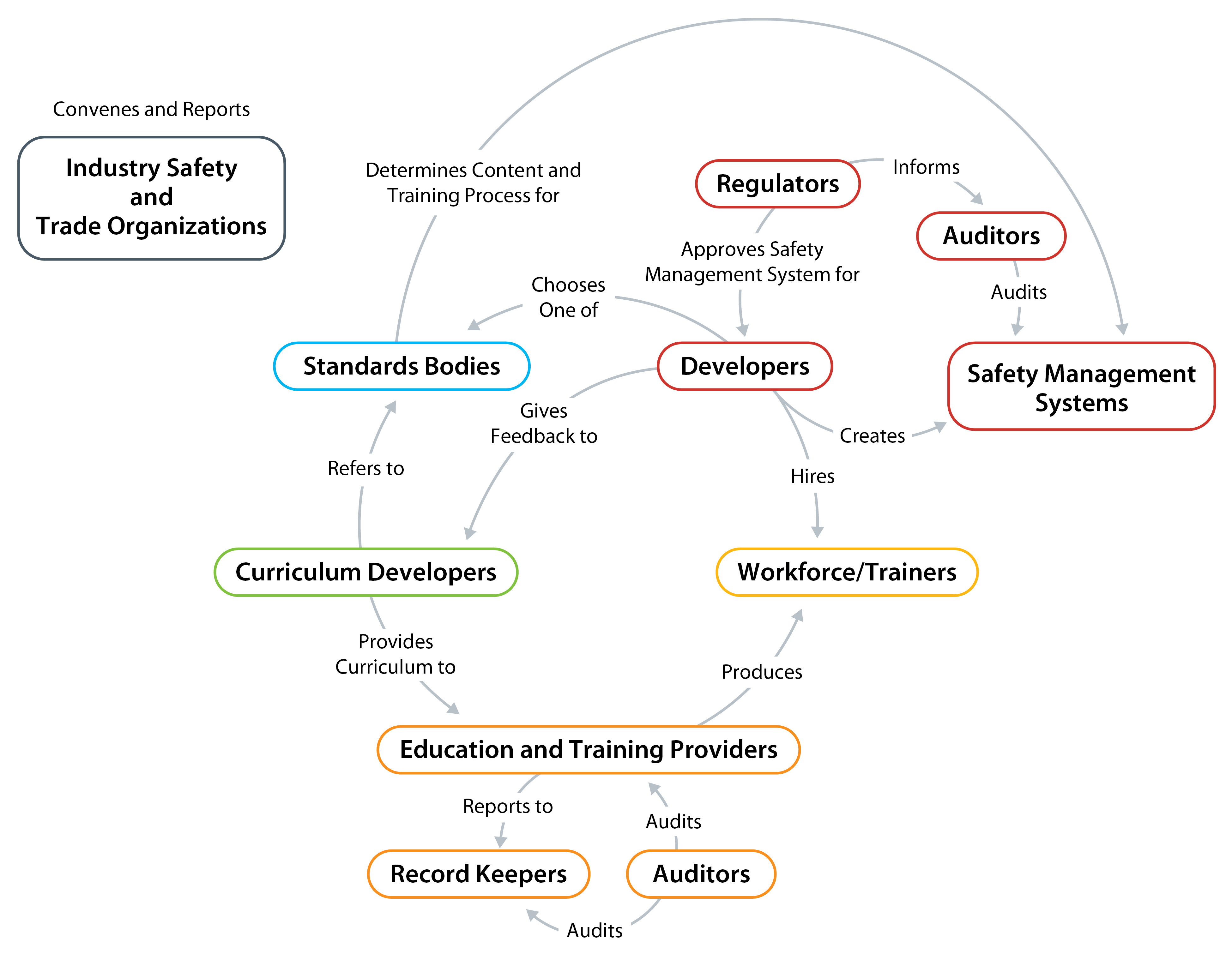

Offshore wind energy safety training is a complex and multifaceted ecosystem. A National Renewable Energy Laboratory team conducted 12 discussions with education and safety training professionals to understand the ecosystem, challenges, and opportunities surrounding offshore wind safety and training from key stakeholder groups’ perspectives. The findings in this fact sheet synthesize their viewpoints. Through our effort, we identified seven key areas that encapsulate the offshore wind safety training ecosystem. They include standards creation bodies, safety management system (SMS) creation bodies, regulation authorities, auditors, curriculum developers, training institutions/curriculum providers, and record keepers (Figure 1). Each key area includes stakeholders with varying roles and responsibilities within the space, and Figure 1 names a few. Those complex relationships are displayed in Figure 1.

Figure 1. Relationship map of key stakeholders that need to be aligned in the offshore wind workforce safety standards and training ecosystem for successful workforce development.

Ecosystem

Safety training standards offer accredited guidance that dictates which processes and systems are sufficient to meet regulation. In offshore wind energy in the United States, there are a few relevant recommended practices (RP) that act as safety training standards from other offshore industries, although no RP specifically for U.S. offshore wind energy exists. These RPs are developed by the associated standards bodies (such as the American Petroleum Institute [API], International Standards Organization, or American National Standards Institute [ANSI]) in conjunction with industry trade organizations (such as American Clean Power Association or American Renewable Energy Standards and Certification Association), who convene industry stakeholders and develop consensus. In the presence of multiple RPs, developers can choose the RP most appropriate for their project to follow and must prove sufficient safety through performance-based audits. Ultimately, standards enable the industry to keep workers safe through increased clarity and accountability of safety training requirements for 1) developers and subcontractors to follow and 2) regulators to enforce.

In the offshore wind energy industry, developers create an SMS in conjunction with subcontractors to ensure offshore workers are sufficiently trained in appropriate safety topics as they relate to their role. In Special Report 310, which evaluates the adequacy of existing regulation and recommends enhancements to regulations for worker health and safety on OCS wind farms, the Committee of Offshore Wind Farm Worker Safety defines the purpose of an SMS as:

These are defined:

The broad intent of a management system for occupational health and safety is to define an organization’s health and safety policies and the responsibilities of key personnel, to identify hazards that can lead to incidents, to determine the risk associated with each hazard, and to take appropriate precautions to decrease the likelihood of incidents and mitigate those that occur. An SMS can provide the framework for an effective safety culture, which is necessary in implementing the organization’s safety goals. The SMS must also provide a mechanism allowing managers to verify that the health and safety policies and procedures produce the intended results and to take any necessary corrective action. Such a safety improvement cycle (such as the “plan-do-check-act” process) places the responsibility for safe operations on the organization through measures of accountability.[3]

Developers submit an SMS as part of a Construction and Operating Plan (COP) to the U.S. Department of the Interior’s Bureau of Ocean Energy Management (BOEM), whereupon the U.S. Department of the Interior’s Bureau of Safety and Environmental Enforcement (BSEE) provides review and BOEM ultimately approves, disapproves, or requires modifications to the documents based on BSEE feedback. During operation, BSEE is responsible for auditing, inspecting, and enforcing adherence to the SMS. BOEM issued basic requirements for U.S. offshore wind energy developer SMS in Subpart H of 30 Code of Federal Regulations 585 in 2009[4], and later was covered by the American Wind Energy Association’s 2012 offshore compliance RP document[5], but BSEE expects SMS content to be dictated via a standards-approved RP. Current guidance defines performance based SMS expectations in the Safety Management System Expectations for Renewable Energy Companies Operating on the Outer Continental Shelf[6] published in March 2023.

In the offshore wind energy safety training and standards creation space, the main regulating authorities are BSEE and BOEM. BSEE has predominant responsibility for “development, oversight, and enforcement of safety and environmental standards”[7] for the operations of offshore energy; however, BOEM and BSEE work collaboratively to establish guidance and review submissions for the offshore wind energy industry. Developers, for example, would submit their SMSs to BOEM as part of their COP, which can be approved, disapproved, or approved with modifications. BSEE would receive and review the SMSs and develop terms and conditions for BOEM’s COP relevant to BSEE jurisdiction. More information about the jurisdiction of BOEM and BSEE can be found in a 2023 presentation on Renewable Energy Split Rule Information and Q&A.[8]

The U.S. Coast Guard (USCG) also acts as a cooperating authority to BOEM and BSEE during the National Environmental Policy Act evaluation of offshore wind energy project permit applications reviewing the proposal based on criteria in Navigation and Vessel Inspection Circular number 01-19[9] and giving recommendations on a case-by-case basis. The USCG doesn’t have authority to approve, disapprove, or permit an offshore wind energy application.

Auditing ensures sustained compliance and maintains standards of safety throughout the offshore wind energy industry. Safety training and curriculum require audits on a regular basis either internally or externally from BSEE, USCG, International Maritime Organization, Center for Offshore Safety, or a third-party industry member, depending on the types of audits required. For example, the Global Wind Organisation’s (GWO’s) Basic Safety training will be audited every 2 years by an independent, GWO-accredited third party. BSEE, a third party, and/or a developer will perform audits of the SMS and worker certifications, and International Maritime Organization creates the audit scheme for USCG safety certifications. Additionally, if a developer is using API RP75, then they will be audited by auditors accredited through the Center for Offshore Safety.

Curriculum development includes the creation of standard, role-specific skill sets, competencies, and qualifications to ensure both trainers and students are trained to the approved safety standards. Some examples of curriculum developers are GWO, Offshore Petroleum Industry Training Organisation, and the Ocean Energy Safety Institute. Curriculum development also includes developing requirements for training providers and learning objectives for workers. Learning objectives are designed in accordance with the approved standards and describe what workers should know and be able to do when the training is complete. Offshore wind energy developers or subcontractors may also create in-house training specific to competencies and qualifications to follow their SMS. In addition, universities, community colleges, unions, and maritime institutions may create curriculum to teach broad knowledge of offshore wind energy and role-specific skill sets. Often organizations that develop curriculum have stated they align with existing GWO standards to meet anticipated recommended practices and industry hiring preferences.

Some examples of existing curriculum include Basic Safety Training and Basic Technical Training standards offered by GWO. Courses in the Basic Safety Training certification include Fire Awareness, First Aid, Working at Heights, Manual Handling, and Sea Survival. Courses in the Basic Technical Training certification include Mechanical Training, Electrical Training, Hydraulics Training, Bolt Tightening, and Installation Training. Other GWO courses include Control of Hazardous Energies, Advanced Rescue, Enhanced First Aid, Blade Repair, Slinger Signaler/Rigger Signal Person, Crane & Hoist Training, Lift Training, and Wind Limited Access. The USCG also certifies providers of Standards of Training, Certification and Watchkeeping. Courses in the basic safety training group include Basic Fire Fighting, Personal Safety and Social Responsibility, Personal Survival Techniques, and Elementary First Aid. Beyond the basic safety training, often more advanced-level courses are needed for workers to specialize in specific offshore wind energy installation or operations activities or to meet specific developer or subcontractor training needs.

Training providers disseminate curriculum by training students and other trainers in role-specific safety training. Involved institutions include community colleges, maritime academies, labor unions, private training companies, and industry employers. These institutions are actively working to understand offshore-wind-energy-specific safety standards and what is likely to be included in developer SMS to avoid duplicating programs that provide similar trainings and ensure the employability of their graduates. In addition, these institutions are working to become certified training providers and to integrate several different training standards into new or existing programs.

Many training providers have started the process of becoming GWO-certified and offering GWO courses because several major manufacturers, developers, and operators are promoting its adoption. Although safety training courses can be integrated into many types of training institutions, some stakeholders suggest that it is easiest to partner with community colleges to provide training, given access to funding and organizational structures. However, other groups point out that integrating safety training through centralized labor unions can allow trainings to trickle down to local labor unions as workers complete apprenticeship programs. Community colleges or maritime academies have also worked with developers, operators, and original equipment manufacturers to understand curriculum preferences to increase industry competitiveness of program graduates. A compiled list of program locations offered by different organizations can be found at the U.S. Department of Energy’s offshore wind energy workforce education and training database.[10]

These groups also point to the importance of creating strategic partnerships to offer training courses. Partnerships include community college contracting private training company certified in programs like GWO, labor unions and maritime academies sending their workers to community colleges for specific safety training, and developers sharing their training requirements with institutions. An example of a contract partnership is the Bristol Community College’s National Offshore Wind Institute, which partnered with GWO and Maersk Training (a GWO-certified training provider). The National Offshore Wind Institute works with industry members, such as Ørsted, GE Offshore Wind, and Mayflower, to develop training to meet industry needs. A third-party audit of the training programs is conducted by DNV. This partnership provides U.S. institutions with the experience and knowledge from Europe to ensure alignment with industry needs—due to the nascent nature of the offshore wind energy industry in the United States. This partnership also supports the development of the offshore wind energy training programs, including GWO curricula, trainings for the trainer programs, purchases of specialized equipment, as well as offerings of other needed training and educational programs.

After a potential or current offshore wind energy worker completes offshore wind energy safety certifications, the record of completion of that course or certification is filed with a record-keeping body. For example, WINDA is a global database designed for verifying the training status of GWO-certified individuals.[11] Curriculum developers, such as GWO or USCG, or the training institution, such as a community college or labor union, help centralize and authenticate records so that training providers, participants, and employers can access and verify employee certifications and enhance transparency in the training process. Additionally, the records kept are an aspect of the SMS and auditing process.

Industry safety and trade organization are entities who span a multitude of stakeholder groups within the offshore wind workforce safety standards and training ecosystem and provide insight into key guidance and/or challenges that the offshore wind energy industry is most currently facing. They act as a connecting group in the industry to help develop ways to achieve the shared goal of safety within the offshore wind energy industry. A few examples of an industry safety organization are G+ Global Offshore Wind Health and Safety Organisation, who releases an annual report on safety incidents and good practice guidance for industry, and International Marine Contractors Association (IMCA) who produces industry guidance and best practices for vessel operations, dynamic positioning, ROV, lifting, marine operations, and training. Industry trade organizations can also contribute to offshore wind workforce safety standards and training, as part of their broader mission to foster collaboration amongst industry members to improve the health and success of their industry. Two industry trade organizations in the offshore wind sector include: the Business Network for Offshore Wind (BNOW) and American Clean Power (ACP). In relation to offshore wind workforce safety standards and training, BNOW promotes activities and collaboration which support the standards and alignment, while ACP is directly involved in standards development as an ANSI-approved body.

Blueprint to Act

Complexity

There are concerns with complexity, for which we provide solutions, including:

Background: Currently, three RPs exist that can be applied to the U.S. offshore wind energy industry SMS creation (ANSI Z-10, API 75, and International Organization for Standardization ISO 4500-1). In addition, API has publicly announced plans to create an offshore-wind-energy-specific RP, API 75-W. American Clean Power Association has also announced plans to create a more prescriptive RP for U.S. offshore wind energy. BSEE has expressed their acceptance of SMS that follow any of these frameworks and will need the support services and processes to audit those SMS and enforce them. The number of those support services that will be needed will only be truly known after the COPs are submitted. Furthermore, developers and subcontractors will need to prepare for performance-based audits within the chosen RP.

Solution: Industry guidance that differentiates the RPs and their appropriate application could help provide clarity for those entities that have not already adopted a preferred RP to follow.

Background: Due to the novelty and complexity of the U.S. offshore wind energy industry, education and training institutions lack certainty about what certifications offshore wind energy workers will need for the occupations they are seeking and what institution should be leading the training efforts.

Solution: A gap analysis that compares curricula could reduce uncertainty in which safety trainings are needed to adequately prepare offshore wind workers, identifying gaps and redundancies between offshore wind energy safety training in reference to current international industry requirements and preferences for offshore wind energy workers. Publicly disseminating that information, along with an updated database of providers (current and pending) could enable stakeholders to coordinate, even if indirectly, on workforce development needs. A database of providers would provide additional value as a mechanism for partnerships.

Coordination

There are concerns with coordination, for which we provide solutions, including:

Background: Organized labor union structures are complex, and their governance varies by location and industry. Many labor unions have trained workers to construct and operate projects on shore, but these skilled workers may lack offshore-specific training and may be unfamiliar with working in an ocean environment. Skill sets and occupations already supported by unions have various levels of transferable safety training and knowledge to the offshore wind energy industry, and many unions near offshore wind energy projects require support to understand what training is relevant for offshore wind energy roles. Standardizing training for the upskilling of organized labor union members is challenging due to the various structures and uncertainty around skills and certifications required to safely enter the offshore wind energy workforce.

Solution: Standardized safety training for unions can be done through multiply pathways. One of the ways to help clarify upskilling requirements and leverage the structure of labor unions is to implement standardized safety training curriculum at the national level of unions, enabling it to reach local unions through their national training organizations. In addition, the same funding mechanisms available at community colleges are not always available to unions. To enable unions to access these funding mechanisms and leverage already existent offshore-wind-energy-specific safety training, local unions could consider partnering with community colleges to have union students trained through established programs. Community colleges have the ability to train GWO, Offshore Petroleum Industry Training Organisation, and Basic Safety Training certifications, as well as welding procedures, electrical control, etc., which could be used to skill and upskill new and existing workers. Additionally, unions and community colleges could partner to set up their own training facilities specific to offshore wind energy or help existing USCG-approved training facilities to provide offshore wind energy safety standards training.

Background: Due to the uncertainty of role-specific training requirements and the large number of stakeholders involved, there are a multitude of piecewise, dispersed pathways for workers to be trained and hired into the offshore wind energy industry. In a few of these pathways:

- Industry can hire union workers that went through gap trainings related to the offshore wind workforce at a community college.

- Industry can hire people trained through community colleges directly.

- Industry can contract with subcontractors who hire or upskill their existing workers through community colleges or maritime academies.

Solution: There needs to be consensus and centralization over what institutions should be accredited training institutions. Due to capacity, awareness, and funding opportunities, maritime academies and community colleges are best suited to offer offshore wind energy safety training and partner with industry and unions for hiring needs and worker upskilling. Regional coordination and agreement between organizations on who will provide specific training could help avoid duplication of resources and improve the sustainability of existing programs.

Background: Education and training institutions (e.g., community colleges, maritime academies, and labor unions) have expressed that more engagement between their programs and industry members (e.g., developers, standards creators, and regulators) is important to understanding what curriculum and certifications are needed to be taught for their students for them to be successful entering the offshore wind energy workforce. Currently, there is no formal platform for effective collaboration to take place, causing barriers in communication between offshore wind energy safety educators, students, and industry.

Solutions: The creation of a cross-sectional working group to discuss updates on safety standards creation, training and curriculum implementation, and effective partnerships between industry and training institutions could increase collaboration between key stakeholders, allowing for a more adequately trained workforce. Enabling increased awareness and coordination between stakeholder groups could help avoid duplicative programs. An already-established group could consider creating a working group to convene and key stakeholders on a recurring basis.

Capacity

There are concerns with capacity, for which we provide solutions, including:

Background: Organized labor union structures are complex, and their governance varies by location and industry. Many labor unions have trained workers to construct and operate projects on shore, but these skilled workers may lack offshore-specific training and may be unfamiliar with working in an ocean environment. Skill sets and occupations already supported by unions have various levels of transferable safety training and knowledge to the offshore wind energy industry, and many unions near offshore wind energy projects require support to understand what training is relevant for offshore wind energy roles. Standardizing training for the upskilling of organized labor union members is challenging due to the various structures and uncertainty around skills and certifications required to safely enter the offshore wind energy workforce.

Solution: Standardized safety training for unions can be done through multiply pathways. One of the ways to help clarify upskilling requirements and leverage the structure of labor unions is to implement standardized safety training curriculum at the national level of unions, enabling it to reach local unions through their national training organizations. In addition, the same funding mechanisms available at community colleges are not always available to unions. To enable unions to access these funding mechanisms and leverage already existent offshore-wind-energy-specific safety training, local unions could consider partnering with community colleges to have union students trained through established programs. Community colleges have the ability to train GWO, Offshore Petroleum Industry Training Organisation, and Basic Safety Training certifications, as well as welding procedures, electrical control, etc., which could be used to skill and upskill new and existing workers. Additionally, unions and community colleges could partner to set up their own training facilities specific to offshore wind energy or help existing USCG-approved training facilities to provide offshore wind energy safety standards training.

Background: Adopting standardized curriculum, certifying training institutions, and training trainers can increase the costs associated with curriculum development. States and federal agencies offer grant funding; however, gaining access to funds can be a challenge for individual organizations.

Solutions: Curriculum developers partnering with training institutions that have access to state and federal funding can increase opportunity for training institutions to gain financial support for curriculum standardization. Partnerships between workforce groups, community colleges, and curriculum development organizations (like GWO) can increase access to grant funding and, therefore, build capacity to standardize curriculum.

Background: Community colleges and unions have expressed the need to use resources efficiently and avoid developing too many programs compared to the workforce demand. Understanding the capacity of workers to meet offshore wind energy deployment goals, and the safety and training certifications needed to successfully enter the industry, can assist in strategically developing training programs and help to ensure an adequately sized and trained workforce.

Solutions: Coordination and collaboration between stakeholders is required to optimize training pathways and meet workforce needs of the offshore wind energy industry. This could be indirect coordination through a database of programs and their respective capacities, or direct coordination through a venue or recurring working group.

Safety Moment

Injuries impact all of us!

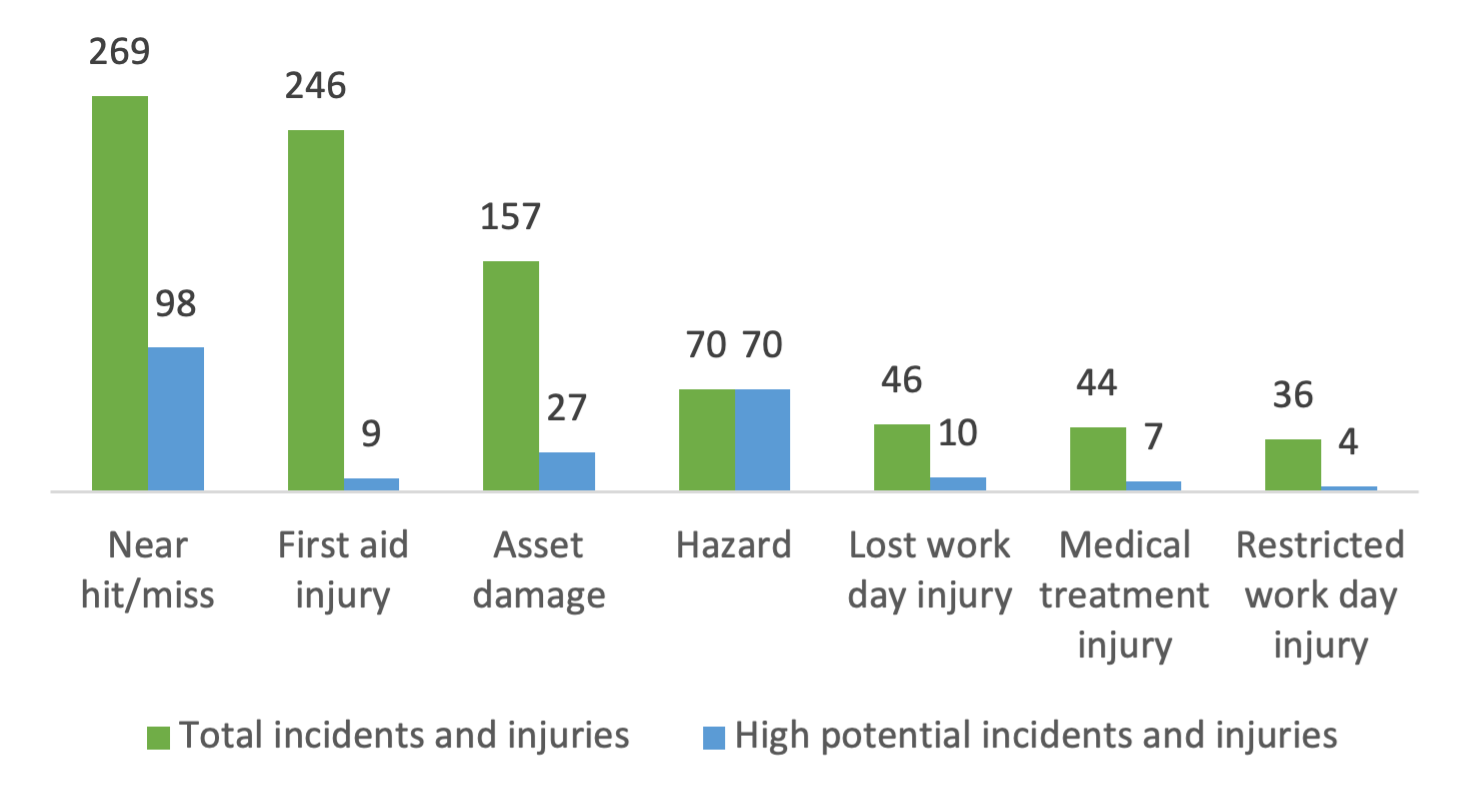

[12]Workplace injuries not only hurt those involved in an accident but can affect their friends, family, co-workers, and employers. They also can have a big impact on business and the wider industry through reduced productivity, lost sales, lower recruitment and retention of workers, lower staff morale, or even facility closures and reputation impacts. In Figure 2, the impacts of safety incidences are shown for the global offshore wind industry’s 44.64 million hours worked over 2022, as collected and reported by G+ Global Offshore Wind Health and Safety Organisation in their latest annual incidence report.

Accidents arise from unsafe behavior and unsafe conditions. Keeping workers safe through 1) adequate and timely training, practice, and performance, 2) a safe working environment, and 3) a strong safety culture is paramount. Safety culture comprises the shared attitudes, beliefs, perceptions, and values among employees about how workplace safety is managed and is cultivated by every individual in the organization. An organization that successfully cultivates a positive safety culture can expect to realize immediate and tangible results in reducing workplace accidents and their associated impacts. Commitment to safety must be communicated throughout every level of the organization.

It is important to master required skills to maintain a safe environment for you and others through training, focus on the task at hand, and be aware of potential hazards that exist. It is everyone’s responsibility to protect the health and safety of themselves and others. If you see an unsafe behavior or condition, stop and correct it immediately!

Figure 2: 2022 Global offshore wind industry incidence summary G+, 2023

Return to topWorks Cited

[1] Jeremy Stefek, Chloe Constant, Caitlyn Clark, Heidi Tinnesand, Corrie Christol, and Ruth Baranowski. 2022. U.S. Offshore Wind Workforce Assessment. Golden, CO: National Renewable Energy Laboratory. NREL/TP-5000-81798. https://www.nrel.gov/docs/fy23osti/81798.pdf.

[2] The Offshore Wind Workforce Network–sponsored by The U.S. Department of Energy Wind Energy Technologies Office and convened by the National Renewable Energy Laboratory–is a group of wide-ranging stakeholders who collaborate and coordinate closely on key workforce issues in the U.S. offshore wind industry.

[3] Committee of Offshore Wind Farm Worker Safety. 2013. Worker Health and Safety on Offshore Wind Farms Special Report 310. Washington, D.C.: Transportation Research Board. https://nap.nationalacademies.org/catalog/18327/worker-health-and-safety-on-offshore-wind-farms-special-report-310.

[4] Code of Federal Regulations. “30 CFR 585 - Renewable Energy and Alternate Uses of Existing Facilities on the Outer Continental Shelf.” In Title 30 “Mineral Resources”, Chapter 5 “Bureau of Ocean Energy Management, Department of the Interior,” Subchapter B “Offshore,” Part 585 “Renewable Energy and Alternate Uses of Existing Facilities on the Outer Continental Shelf.” July 15, 2015. 76 FR 64623, 43 U.S.C. 1331 and 1337. https://www.govinfo.gov/app/details/CFR-2015-title30-vol2/CFR-2015-title30-vol2-part585.

[5] American Wind Energy Association. 2012. AWEA Large Turbine Compliance Guidelines: Offshore Compliance Recommended Practices (2012) Recommended Practices for Design, Deployment, and Operation of Offshore Wind Turbines in the United States. Washington, D.C.: American Wind energy Association. https://offshorewindhub.org/sites/default/files/resources/awea_9-16-2012_oswrecommendedpractices.pdf.

[6] Code of Federal Regulations. “30 CFR 585 - Renewable Energy and Alternate Uses of Existing Facilities on the Outer Continental Shelf.” In Title 30 “Mineral Resources”, Chapter 5 “Bureau of Ocean Energy Management, Department of the Interior,” Subchapter B “Offshore,” Part 585 “Renewable Energy and Alternate Uses of Existing Facilities on the Outer Continental Shelf.” July 15, 2015. 76 FR 64623, 43 U.S.C. 1331 and 1337. https://www.govinfo.gov/app/details/CFR-2015-title30-vol2/CFR-2015-title30-vol2-part585.

[7] Sligh, Kevin and Elizabeth Klein. 2023. “BSEE/BOEM Renewable Energy Split Rule Information and Q&A: AA003 Reorganization of Title 30— Renewable Energy and Alternate Uses of Existing Facilities on the Outer Continental Shelf.” Presented at BSEE/BOEM Split Rule Workshop. BSEE and BOEM, Washington, D.C., Feb. 2, 2023. https://www.bsee.gov/sites/bsee.gov/files/bsee-boem-split-rule-workshop-bsee-boem-020223.pdf.

[8] Refer to Footnote 6.

[9] USCS. 2019. Navigation and Vessel Inspection Circular No. 01-10. Washington, D.C.: U.S. Department of Homeland Security. COMDTPUB P16700.4. Aug. 1, 2019. https://www.dco.uscg.mil/Portals/9/DCO%20Documents/5p/5ps/NVIC/2019/NVIC%2001-19-COMDTPUB-P16700-4-dtd-01-Aug-2019-Signed.pdf?ver=2019-08-08-160540-483.

[10] U.S. Department of Energy. “Education and Training Database.” OpenEI. Accessed May 2023. Last modified May 16, 2022. https://openei.org/wiki/Offshore_Wind_Workforce/Education_and_Training_Database.

[11] Global Wind Organisation WINDA. 2023. “Training Providers.” Accessed June 2023. https://winda.globalwindsafety.org/training-providers-map/.

[12] Text content inspired by Dover Artificial Lift’s Weekly Safety Moment Newsletter for April 17th-23rd, 2016. A database of their Safety Moment Newsletters can be accessed at https://www.pinterest.ca/albertaoiltool/safety-moments-at-alberta-oil-tool-dover-artificia/.

Publication Information

Publication Information

DOE/GO-102023-6075

This work was authored by the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-08GO28308. Funding provided by U.S. Department of Energy Office of Wind Energy Technology Office. The views expressed in the article do not necessarily represent the views of the DOE or the U.S. Government. The U.S. Government retains and the publisher, by accepting the article for publication, acknowledges that the U.S. Government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this work, or allow others to do so, for U.S. Government purposes.

This factsheet was sponsored by DOE WETO and created by NREL to identify the current status, opportunities, and challenges in safety training standards and alignment within offshore wind industry. If you would like to get involved in the Offshore Wind Workforce Network or feel your organization is misrepresented or not included in this factsheet, please contact us at WindWorkforce@nrel.gov.

Return to top